|

|

|

|

|

|

|

|

|

|

|

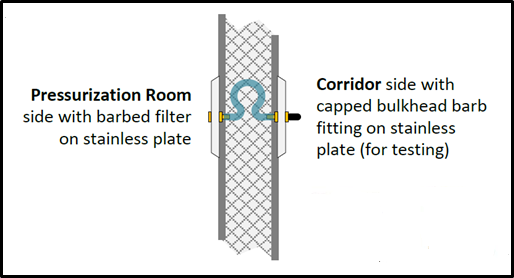

Welcome to CCG AutomationCCG Automation, Inc. is a leading provider of building automation solutions, dedicated to creating high-quality, comfortable buildings with low energy consumption and user-friendly systems. Unlike others, CCG prioritizes the total cost of ownership throughout the building's lifespan, ensuring that customers can afford their utility bills from project completion to the building's end. Unfortunately, it's all too common to see brand new buildings with exorbitant utility bills. This is often the result of prioritizing the lowest upfront cost rather than considering the contractor with the lowest total cost of ownership. Regrettably, this neglected approach in today's construction industry leaves building owners struggling to afford their utility bills, causing undue hardship. If you're facing the burden of high utility bills, planning to construct a new building, or simply in need of a building automation system upgrade, look no further than CCG Automation. We have the solution you've been searching for. Critical Room Pressure TestingControlling the environment in a healthcare facility is very critical to the safety and comfort of patients, and the productivity of the healthcare team. An important aspect of a properly controlled environment is the pressure relationship between rooms. An example of a room requiring positive pressure with respect to its adjacent spaces is an Operating Room (OR). A positive pressure is maintained in the OR to prevent airborne pathogens from entering the surgical space - protecting the patient and maintaining equipment cleanliness. A room requiring negative pressure with respect to its surrounding spaces is an Airborne Infection Isolation Room. Negative pressure is maintained in the Isolation Room to contain airborne contaminants and exhaust them out of the building. At CCG, we are responsible for the proper pressure control of these spaces, in addition to the Temperature and Humidity. A Room Pressure Monitor (RPM), which reads the difference in pressure between the controlled room and its adjacent space, is installed and wired to the building automation system. This provides a digital readout of the difference in pressure between the two spaces. As with any technology, maintenance is required and issues arise, and verifying the readings of the RPM is necessary. To verify the accuracy of these devices a test instrument with two probes needs to be utilized. One probe reads the pressure in the controlled room, while the other reads the pressure in the adjacent space. Imagine a technician holding a meter outside the OR door, running a plastic tube under the door (at least 3 feet into the space so the opening under the door doesn’t impact the readings), while keeping the door closed to get an accurate reading. There is so much wrong with this process. First, taking a tube from a technician’s truck and running it into the sanitized OR is counterintuitive. Second, during the daytime, when these problems are usually found, the OR is hopefully booked for the day. Having a technician with a tube at the door of an occupied OR isn’t productive or safe. If the room has a seal under the door there is an added issue where the door will need to be open to insert the tube, which could result in faulty readings. Where rooms require an RPM, CCG installs a through-the-wall test device that allows our technicians to remove a rubber cap and plug their test instrument onto the fitting to read the pressure in the critical room - while standing outside the room, not in the doorway. The above diagram shows a cutaway of a wall between a critical room and its adjoining space. A rubber tube is used as a conduit between the two rooms. The photo above shows the pressure plate on the left with a filter in the middle, which is installed in the pressure-controlled room. The plate on the right, with the barbed fitting, is in the hallway in the case of an OR. Small things can have a great impact. It takes a committed creative team to think outside the box.

|

Company NewsUH Ahuja Medical Center Recognized for Energy SavingsWe are excited to announce that CCG Automation, Inc. has received the Innovative Energy Project of the Year Mid-West US Award and the Runner-up for the 2024 International Award: Energy Project of the Year: US from the Association of Energy Engineers (AEE) for the UH Ahuja Medical Center project! CCG Helps EHOVE Career Center During Pandemic EHOVE Career Center has a new tool called needlepoint bi- polar ionization as part of its safety & wellness efforts during the pandemic that will also be a long-term asset. The ionization system is very effective in killing COVID-19, as well as other viruses, bacteria and molds, including influenza. Akron Children's Hospital Considine Building Win Energy Award The American Society for Health Care Engineers announced that Akron Childrens Hospital has won an Energy to Care Gold Standard Award. Energy Project of the Year at Strasburg-Franklin Local Schools CCG was recognized by Association of Energy Engineers. Leetonia Exempted Village School See Big Reduction in Energy Check out the message we just received from Leetonia Exempted Village Schools! CCG Automation Completes Campus Wide Metering Project at Akron Childrens Hospital CCG Automation recently completed a campus-wide metering project at Akron Children's Hospital to help track energy usage throughout the campus. Company BlogContinuous ValidationIncreased performance and reduced utility consumption leads to success for Akron Children's Hospital. Never Enough MoneyYou get what you pay for. Often, you will find that an initial low cost is the most expensive way to go. Before/AfterImagine how much more productive and healthy occupants are when they are in a comfortable work space. |

| To see how your building is performing, check out our BTU Calculator. CLICK HERE. |